Balancing Demand Supply at Swiggy

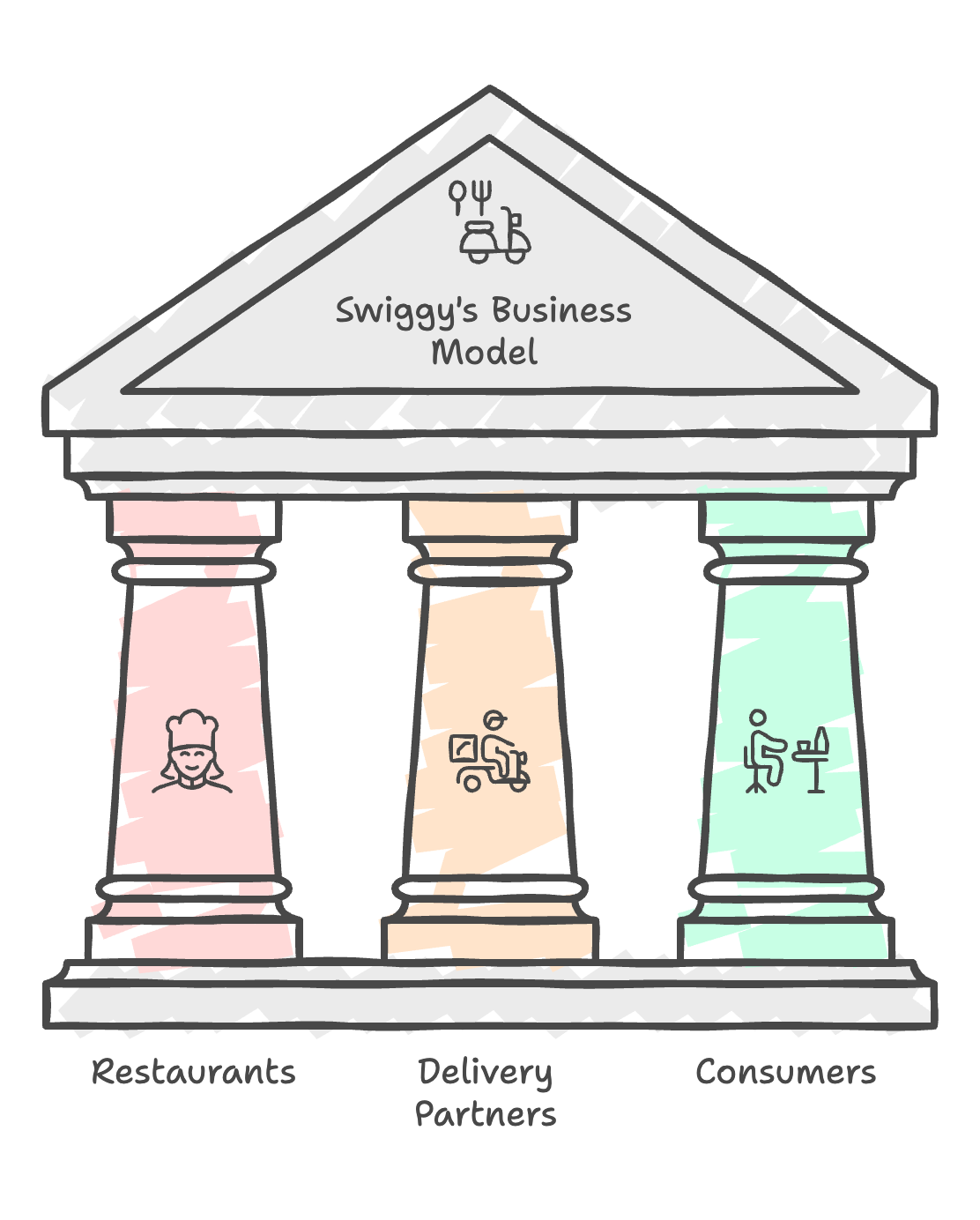

Swiggy is built on three pillars:

- Restaurants (they make the food)

- Delivery Partners (they bring it to your doorstep)

- Consumers (they crave paneer tikka at midnight)

Restaurants and delivery partners together form the "supply" while hungry customers create the "demand".

In hyperlocal delivery, matching these two in real-time is do-or-die—if you have too few drivers or too many orders, customers wait, get hangry, and eventually bail. If you over-staff, you're lighting cash on fire.

Balancing this equation drives core business outcomes: faster deliveries mean happier customers, which translates into more orders, higher frequency, and a healthier bottom line.

As the Demand-Supply Planning Lead, I basically played tug-of-war with the following levers:

Supply Side Levers

- Driver Supply - Straightforward in theory: need more drivers, go hire. In practice, it was a world of forecasting demand at the hyperlocal zone level (over 2,000 such zones across 500+ cities), translating that into headcount needs, and then recruiting drivers through online channels and referral programs. Believe it or not, my early forecast models started off in Excel before we migrated to more sophisticated tools.

- Driver Incentives - We tuned incentives (wages, bonuses) to coax more drivers into logging in exactly where and when we needed them. Each zone has its own elasticity—how much do you have to pay for that next driver to sign on? Balancing cost vs. coverage was an art form (and occasionally a white-knuckle ride).

- Order Batching - Allowing one driver to deliver multiple orders in a single trip. This is a powerful knob to turn: ramp up batching, and your existing drivers can handle more orders, effectively increasing your capacity without adding headcount. But push it too far, and you risk delays.

- Third-Party Logistics Partners - During peak demand or tight driver availability, we could bring on third-party logistics partners (like Shadowfax) to handle the overflow. A big relief valve whenever we stared down the barrel of a weekend dinner rush.

Demand Side Levers

- Discounts - Fewer discounts = less frenzied ordering. Decrease or remove them in high-stress periods to keep demand in check.

- Long-Distance Orders - Disable certain far-flung deliveries to cut down on travel time and free up drivers for local orders. Faster deliveries mean happier customers.

- High Wait Time Restaurants - If a restaurant habitually takes ages to prep food, we could hide them temporarily from a zone's feed. That keeps overall efficiency high and helps manage supply constraints during peak times.

Firefighting and Growth

Balancing these levers in real time—across thousands of zones, in the middle of a pandemic, while fending off fierce competition—was both thrilling and exhausting. It taught me the power of first-principles thinking: sometimes the best move is to break things down to root causes, load up an Excel sheet, and experiment rapidly. Along the way, I also learned to manage cross-functional teams, talk numbers with the data squad, and handle real-world chaos with ground ops. And yes, I made some incredible friends who could parse a demand curve quicker than you can say "extra cheese."

That's Swiggy in a nutshell—and my role in making sure the country's food (and quick commerce) cravings got satisfied on time. In a business where your dinner's arrival time can make or break the bottom line, it was an experience that taught me to keep both eyes firmly on the balance between supply, demand, and the levers that keep them singing in harmony.